Measuring true “costs of production” to close the Circularity Gap

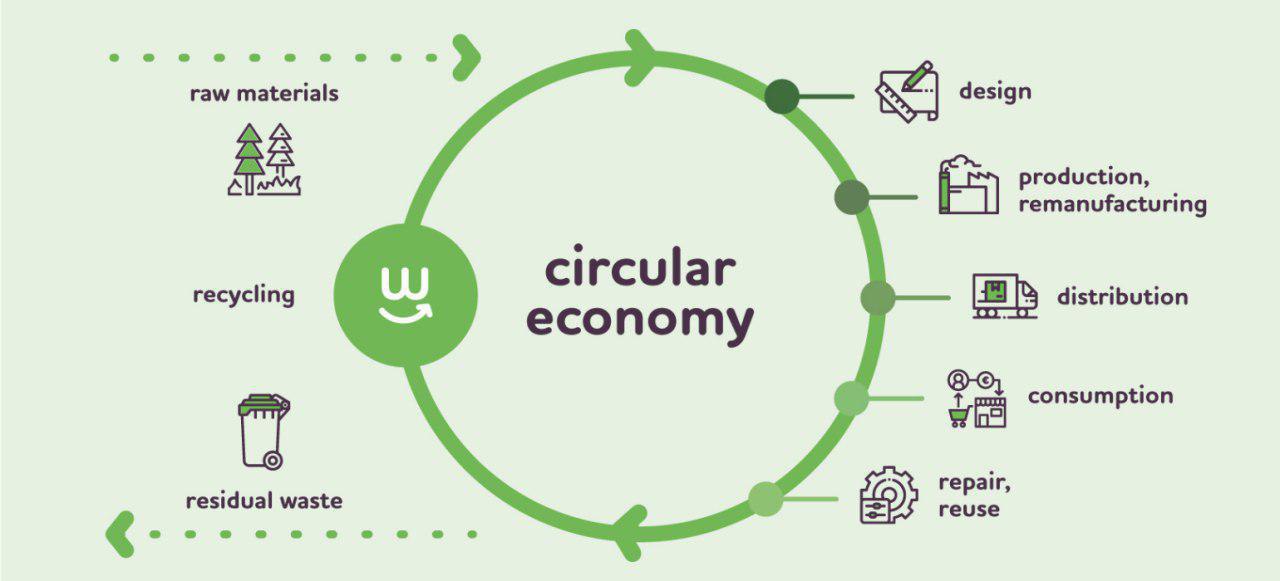

In a number of earlier Posts, we commented on the importance of embracing a Circular Economy and how our Platform as-a-Service can help in this process. In the Circular Economy, the aim is to eliminate waste and keep resources in use for as long as possible with raw materials recovered and reused at the end of a products life.

We have said many times:

“we use nature because it is valuable, …we lose nature because it is free”.

Twentieth century Industry was degenerative by design. We took Earth’s natural resources, turn it into something we wanted and after use, threw it away. This was the consumption model of the 20th Century where business was motivated solely by profit. This destructive model is linear, greedy and wasteful in nature, and works contrary to regenerative laws of nature.

This is the case because we do not measure and price the benefit of having clean air to breath or available clean water to drink. Nor do we cost in, the CO2 being emitted in an extraction, manufacture / production process or the damage to the environment and loss of biodiversity. Nor is this cost carried forward, in any balance sheet, in the cost of the end product / products. The 20th Century has concerned itself with growth. Growth at no price (as not all costs of production are measured). As demand for raw resources continue to increase over time, with an increasing population, production processes reliant on the raw materials MUST consider every avenue, other than the consumption of our rare and scarce virgin natural resources, as the inputs to production.

As we approach 2020, we all hope Industry can embrace the Circular Economy. Leaving 2019, “Our world economy is only 9.1% circular, leaving a massive ‘Circularity Gap’. Closing the circularity gap serves the higher objective of preventing further and accelerated environmental degradation and social inequality.”

Recycled production inputs must make up an increasing and growing percentage of raw material requirements towards our global wants. This also means a change to our supply chains from vertical to circular also.

The Energy Transitions Commission estimates that a more circular economy could reduce CO2 emissions from plastics, steel, aluminium and cement industries by 40% globally and by 56% in developed European economies by 2050.

The environment4change team believes many more organisations want to do the right thing, would engage in the discussions and plans around re-engineering of processes and composite choices if help was available. The help needed is in respect of overcoming some of the ‘barriers’ to becoming a circular closed economy. Education and knowledge of alternatives are parts of the solution that will be addressed via a strategy of co-operation and collaboration and this is enabled via the environment4change platform.

Enabling others to become circular is an important part of our global environmental strategy. Part of enabling this circularity to exist, in the neediest global hotspots, is the determination to invest in processes, plant and equipment to enable and complete this critical circular architecture. Creating a global directory of partners, reforming polluters and environmental organisations, will precipitate a change in attitude, away from a blame game to one where a global shared opportunity and responsibility is both recognised and acted upon. This is part of the environment4change marketplace and represents a module within the Platform as a Service architecture.